iHemp + iBinder = iHempCrete

Non-toxic, Breathable, Carbon-Negative, Termite Free, Fire-Proof

iHempCrete is non-structural, natural, renewable, alkaline, breathable, energy saving insulation that provides thermal mass AND thermal conductivity in one material blend

Bag dimensions: 31" x 14" x 10" (78 x 36 x 25cm)

For bag/pallet or LCL please use our order form

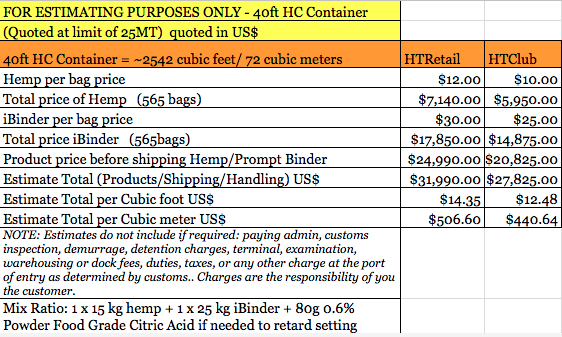

Freight Estimates (US$):

Eastern USA - $7-9,000

Mid USA - $8-10,000

West Coast USA - $9-11,000

Australasia ~$12,000

Note:E.I.N. or Federal Tax ID on the invoice is required for all orders into USA.

Order Here

Weights and Measures

1 x 15 kg bag of Hemp mixed with our 25 kg bag natural cement will make ~4.5 to 5 cubic feet of ”Hempcrete”

Q. How many bags of Hemp do I need for a 12" thick Hempcrete wall ?

A. Calculate length of wall x Height of wall = total square footage.

Now divide by 4.5 to get number of 15 kg (33 lbs) bags of hemp you'll need for a 12" thick wall.

Q. How many people do I need to install Hemp on site for either a new build or retrofit project ?

A. 5-6 with enthusiasm !!!

Q. So - how much does it cost to cast Hempcrete "in-situ" ?

A. 1 person mixing, 1-2 people forming, 2-3 people placing & tamping = 5-6 workers at their local hourly rate per person (and depending on size of mixer) to cast an average of ~120 square feet per day (~3.5 m3).

Statistic:

Average size of new home in America today

~2500 sq ft

Example:

2500 square foot house with 9 foot (2.7m) ceiling less 25% for windows/doors = 1350 cubic feet (f3)

Divide 1350 by 4.5 f3 = number of bags of Hemp/Lime = 300 bags of hemp + 300 bags of our iBinder.

Materials:

Cost per THC pricing per 20' container (delivered to site):

$18 per f3 x 1350 f3 = ~US$24,300 (estimate)

Scaffolding, Mixer, forms, misc. are extra

Labor:

Imer 750 mixer = 4 bags per hour mixing = 32 bags per day x 4.5 f3 = 144 f3 per day

1350 f3 divided by 144 f3 per day = 10 days installation time (weather dependant)

Imer 360 mixer: 3 bags per hour = 24 bags per day x 4.5 f3 = 108 f3 per day

1350 f3 divided by 108 = 13 days installation time (weather dependant)

contact us here for more info.

Complete our Install Survey and one of our Hemp Team will make contact to discuss your project and help with costings.

for current Hemp Building Workshops schedule go here

A TON of Hempcrete is estimated to absorb and sequester an additional 25% its own weight (~250 kg of CO2) over 100 years.

CO2 sequestration - Hempcrete is a carbon sink with a low carbon footprint. With 80-90% of Hempcrete composition as hemp shiv, the majority of CO2 sequestered by Hempcrete is in the hemp growth with the remainder absorbed in the process of “carbonation”. This is the process where the lime-based binder absorbs carbon from the air continuously over time, petrifying the hemp shiv.

Generally, Hempcrete is estimated to sequester 110 kg per cubic metre (depending on transportation) which means large-scaled projects have the capabilities of drawing tonnes of CO2 out of the atmosphere.

1 cubic meter (m3) = 35 cubic feet (f3)

1 cubic yard (y3) = 27 cubic feet (f3)

1 Kilogram = 2.2 pounds

1 Metic Ton = 1000 Kilos or 2200 pounds

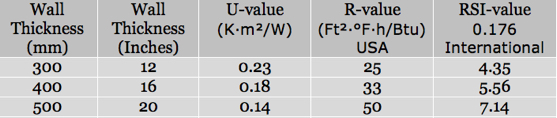

Typical Insulation Values

R-value (US) = RSI × 5.678263337

RSI (SI) = R-value × 0.1761101838

Construction costs may be reduced by:

- Shallower foundations

- 30-40% less lumber, labor in framing

- Lower transport costs of materials to site

- Lower finish costs

- Discounted Insurance costs

- Reduced mechanical (HVAC) requirements

- NO termite fumigation needed after build

Typical Hemp Hurd (Shiv) Composition

Cellulose: 44 - 55%

Hemicellulose: 16 - 18%

Lignin: 4 - 28%

Extractive Substances: 4 - 18%

Other Substances: 6 - 7%

Hempcrete Tri-Fold (2.9mb)

Hurd Specifications (57kb)

Thermal Mass (41kb)

Hemp Technologies assumes no liability from those who decide to mix and use DIY “Hempcrete” binders. Customers should consult local building permitting offices and/or use a licensed general contractor, architect, and/or engineer for all construction projects."